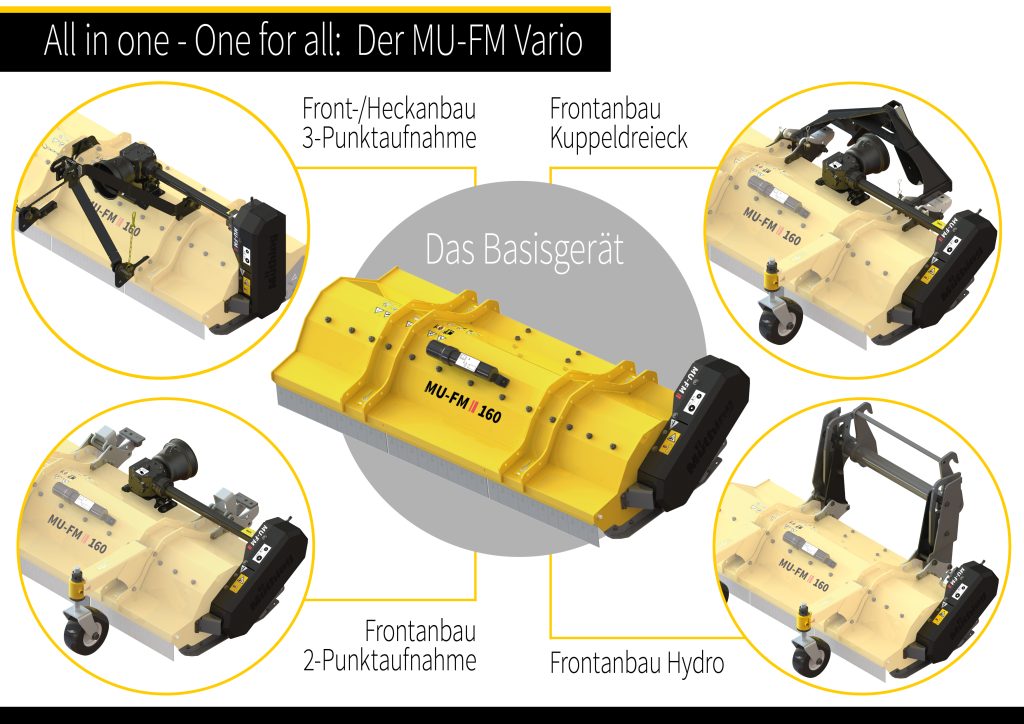

The new MU-FM Vario series as a modular system – flexible and robust thanks to its wide range of configuration options.

Müthing: Modulare MU-FM Vario Baureihe – maximale Flexibilität für Anwender und Händler Nach dem Motto „ONE FOR ALL – ALL IN ONE“ präsentiert Müthing die neue Baureihe MU-FM Vario. Changing customer requirements and the wide variety of different mowing and carrier vehicles have prompted Müthing to develop a new flail mower series for landscaping. Under the motto “One for all – All in one”, Müthing is presenting a flexible and robust flail mower that can be configured variably according to customer requirements and attachment variants thanks to its design as a modular system. .

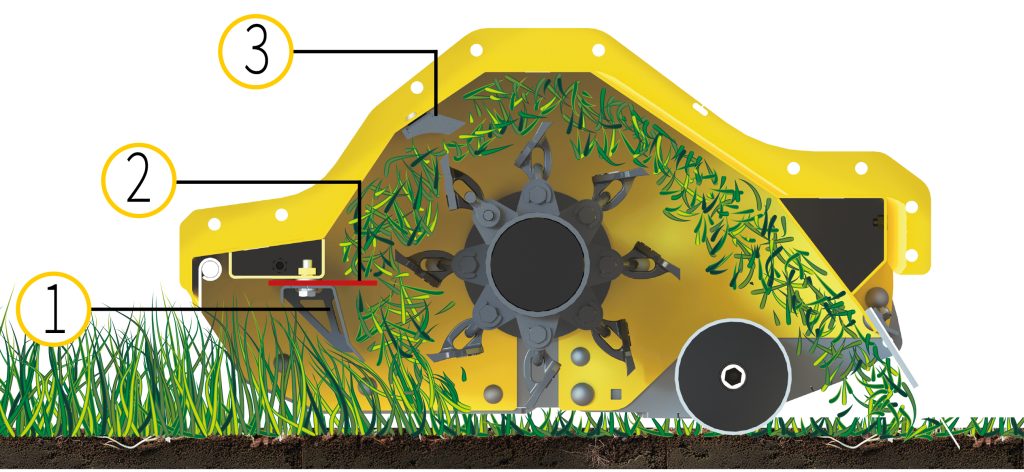

The new FM-Vario will of course also be equipped with Müthing Vario technology in the future. The Vario cutting bar for infinitely variable adjustment of the cutting gap is fitted as standard and allows users to customise the work result to suit their individual requirements. The short-cut angle will also be available as an option for the FM-Vario in future, which is primarily used for fine turf cutting. The implement is available with working widths of 1.20 – 1.60 m.

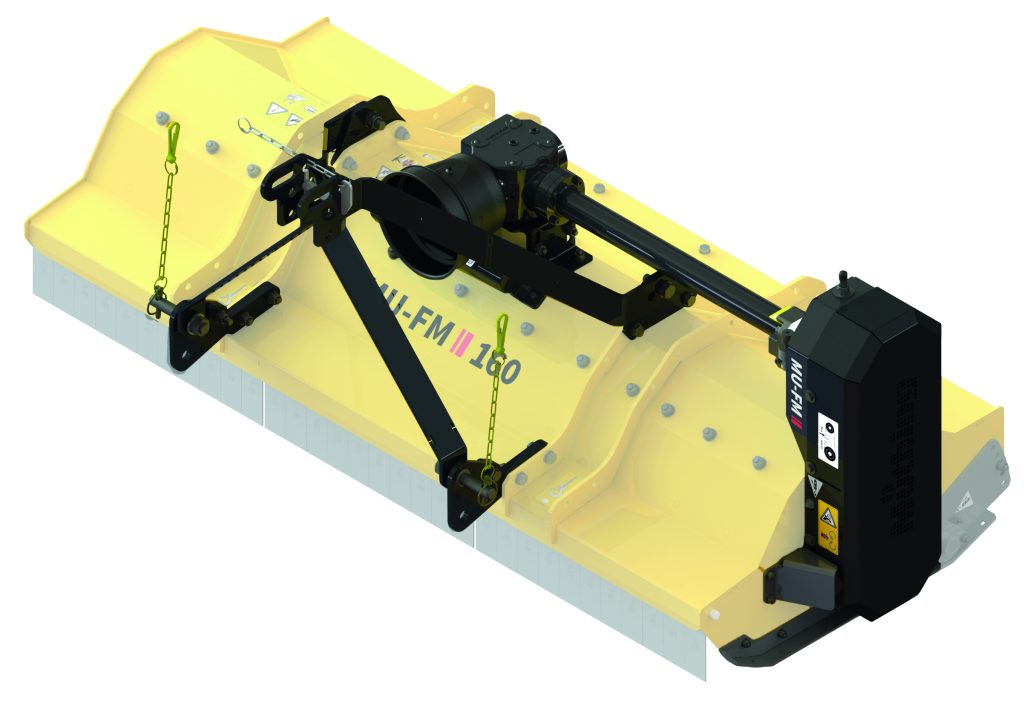

The FM-Vario can be flexibly configured thanks to its intelligent modular system. The machine can be used either with front or rear attachment as well as on yard and telescopic loaders. In addition to front attachment via the 2-point linkage or coupling triangle (Cat. 0 or Cat. 1N), a variant with 3-point linkage Cat. 1 for front and rear attachment will also be available in future. Various customised mounting parts are also available for a wide range of carrier vehicles.

To enable adaptation to the vehicles on the market, Müthing offers a wide range of different transmission variants in terms of transmission position, rotation speed and rotation direction. The equipment covers a power range of 20 – 50 HP.

In addition to various transmission variants, a wide range of hydraulic drive configurations will also be available for the new MU-FM Vario in future. Additionally, to the familiar gear motors with 40 – 70 l/min, an axial piston motor with up to 45 l/min at high working pressure is also available.

The front mounted “BEEHAPPY” insect rescuer can also be added as an option. This considers the efforts being made to protect the entire ecosystem, including insects and small organisms above the soil. The implement can also be configured as a 4-wheel variant instead of using a support roller, which minimises the roll-over area extremely.

Other technical highlights include the redesigned front support wheels with optimised maintenance points, an improved drive concept, variable coupling points for mounting parts and supporting legs and the new user-friendly support roller adjustment function. In addition to the screw-on wear insert made of steel, a lightweight and noise-reducing variant made of plastic is also available. The MU-FM Vario modular system is rounded off by the screw-on Hardox wear runners.

When designing the implement, the focus was on developing a very versatile and robust machine with a low dead weight. The simple handling, above-average work results and maximum safety verified by a thrown-object test in accordance with ISO/WD 17101-2 also offer interesting possibilities for customers and Müthing dealers alike.

Müthing GmbH & Co. KG, headquartered in Soest, is a pioneer in innovative mulching and groundcare technology in the agricultural machinery and landscaping sector.

The Müthing MU-FM Vario is expected to be available from spring 2025.

Images